Slate tiles: an incorrect term?

Traditionally, the term tile has been used to denote an individual piece of baked clay that is placed on a roof for the purpose of channelling rainwater.

The appearance of more and more artificial products that try to imitate natural slate has led to the term being extended to include the term ‘slate’ as well. Thus, it is common to hear the expression “slate tile” to refer to the pieces of natural slate placed on a building to form the roof.

However, professionals in the sector (producers, installers, architects) tend to refer to the product simply as slate, avoiding the word tile. This way they try to differentiate it and highlight the value of the natural value compared with the artificially-produced ceramic product.

Differences between ceramic tiles and slate tiles

Ceramic tiles

The main component of ceramic tiles is the clay that is used to make them.

Their manufacturing process consists of various stages or processes: crumbling and mixing the clay, grinding the clay, kneading (water is added to form the paste), final mixing and extrusion (the air is extracted, more water is added and the clay is compressed), cutting (to give shape to the piece), drying (the water is removed), glazing and finally baking (the tiles are placed in a kiln for 24 hours).

The tiles usually contain additives such as barium carbonate, which is used to avoid efflorescences (white marks) and glazes that are used to achieve the desired finish.

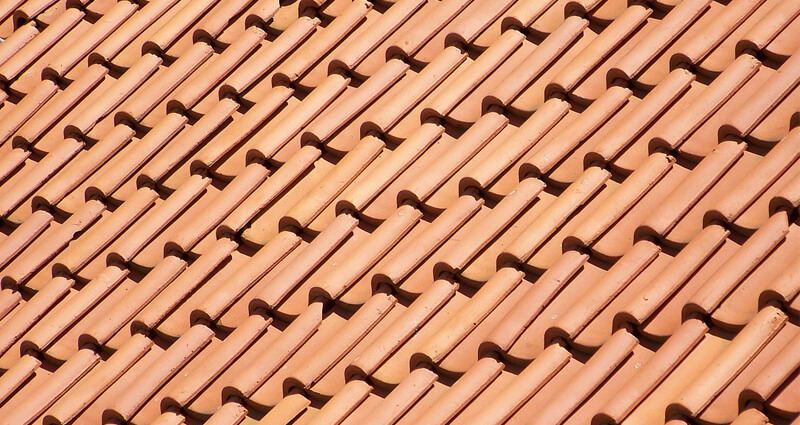

There are different tile designs, the most popular ones being Arabic tiles (or barrel tiles), which have a curved shape, and Roman tiles, which have a flat central piece (canal piece), raised sides and a rounded roll.

Natural Slate tiles

Natural slate is a metamorphic rock of sedimentary origin that dates from the Ordovician period (550 million years ago). It is primarily made up of quartz, sericite and minerals from the chlorite group.

Its colour depends on the mineral structure and size of the mineral grains that make up its composition, which is why each piece is unique and inimitable.

A slate tile is the result of split the large blocks extracted from the mines and quarries into pieces of the desired thickness. Unlike ceramic tiles and other substitute products, the production process for slate is simple and does not require the use of chemicals or additives.

In order to obtain the product that is installed on buildings, only mechanical transformation processes are needed, the majority of which are carried out by hand by skilled craftsmen, such as sawing (the blocks that come from the quarry are cut into different sizes), carving (the slate is shaved down into sheets) and bevelling (the slates are bevelled to help the water flow).

This rock comes from clay sediments that have been subjected to high pressure and temperatures over millions of years. The slate has already been moulded and “baked” by nature, so there is no need to use kilns in the manufacturing process.

Whichever word you use to refer to slate, the important thing is to know the differences between the different materials used in roofing, and to understand that natural slate is a more most ecological and long-lasting option.

Slate is a 100% natural product that is only submitted to extraction and shaping processes. You can read here about the natural slate life cycle.