The truth about Bending Strength

Bending Strength, also known as Flexural Strength, Breaking Load or Modulus of Rupture, is one of the main properties of roofing slates. This test is found in the four roofing slate standards: European EN 12326, USA ASTM C406, Chinese GB/T 18600 and Indian IS 6250.

Together with the water absorption test and sulphur atmosphere exposure, bending strength test forms the common core of roofing slate standards. However, what does Bending Strength really mean? Roughly, it is the maximum strength a roofing slate shingle can stand before it ruptures.

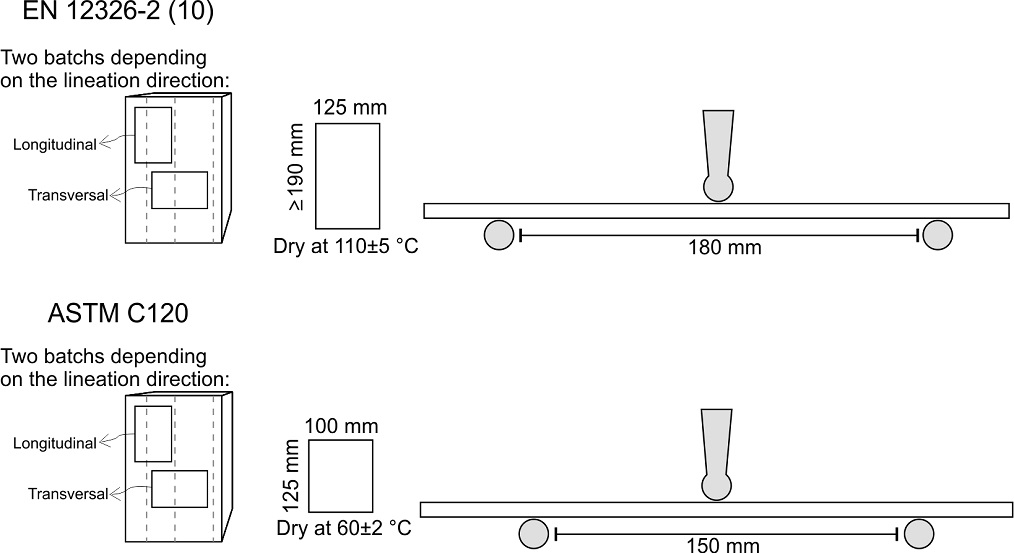

The test calculates this strength by applying a constant increasing force on the middle of a slate shingle using a bar. This slate shingle is supported at its ends by two cross bars. The force is applied until the slate breaks. This setup is called “three-point bending (or flexural) test”, and it is very common in engineering to determine the bending-flexural properties of a material.

Bending Testing Machine

On roofing slates, it is measured in parallel and transversal to the grain direction. Usually, if the shingles are well fabricated, the grain will match with their length. This is known among the miners as “to cut on grain”. In fact, Bending Strength is calculated along and across the grain, or in longitudinal and transversal directions. The longitudinal value should always be higher than the transversal; otherwise, the slate is not cut on grain.

Once we know the force needed to break the roofing slate shingle we can calculate the value for the Bending Strength (the formula is not complex, but I don’t like formulas on my posts. If you are interested, take a look at the Wikipedia page for “Flexural Strength”).

An important element of this formula is that the thickness is included in it, but the Bending Strength does not depend on it. This doesn’t mean that a nice and thin shingle for the French market can uphold the same weight as a thick and solid shingle for the Scottish market, not at all. The thicker the shingle, the higher the force you will need to break it.

Think about it, with enough thickness, any material can resist the weight of an elephant, but some materials will need less thickness to support the elephant, and that is expressed by their Bending Strength. The higher the Bending Strength, the lower the thickness needed for the elephant. The value of Bending Strength fits for all thicknesses of a given roofing slate.

According to test reports, the European EN 12326 gives the values for the Average Modulus of Rupture (remember, it is the same) and the Characteristic Modulus of Rupture, which is the Average Modulus of Rupture with a statistical correction and it is always lower than the Average Modulus. I personally always use the Average Modulus of Rupture.

On the other hand, the American ASTM C120 gives the values for the Breaking Load (again, the same measure) for a given thickness. But wait, if the Breaking Load does not depend on the thickness, why does ASTM include it on its test report? Well, I guess it is just a matter of customs. The USA market is used to reading and dealing with these values on the test reports.

Schematic setup for the European and American Bending Strength tests

And now, the ultimate question: do roofing slate shingles fail in the real world? Not really. The normal values of Bending Strength we are working with are very much above the breaking threshold. In fact, when can a shingle break? Right now only two situations come to my mind, someone walking on the roof and snow/ice accumulation.

The first situation is not common since a slate roof is not for walking on. Only a professional installer should walk on the roof when necessary.

Then we just have snow/ice accumulation. For example, the force applied by 10 cm of wet snow on a slate roof with 35° slope is calculated in the book Slate as dimension stone, as 0.4 MPa. Normal values of Bending Strength for roofing slates are around 50 MPa, so we are a couple of orders of magnitude below the limit.

Roofing slate does not have problems with Bending Strength. However, maybe you have heard someone talking about a roof with some broken shingles. This is very uncommon, especially considering the total number of slate roofs installed every year that last decades without any problems . There are always exceptions, and they are almost always related to very poor-quality roofing slates and/or defective installation. Again, make sure you look for a professional to install your slate roof.

Finally, it is good to have a roofing slate with high Bending Strength values, but the most important is to have a strong and reliable company to back it up. Quality is not just about some test values on a certificate; it is about the whole company and its understanding of your needs.