Everything you need to know to ensure a high-quality slate roof installation

A slate roof installation involves several aspects that must be considered during the design process, such as the site’s exposure to wind and rain. Keep reading to learn everything you need to know before you start designing your roof to ensure the best performance and durability, and the key considerations when using and preparing to use slates and other roofing materials.

The primary aspects to be considered for designing a roof

Environment and site exposure

The buildings environment and the weather conditions to which it is exposed to are essential aspects when designing a roof. The design and technical details will not be the same for a project located in a sunny, dry region to a rainy region. The main factors to consider here are exposure to wind and rain.

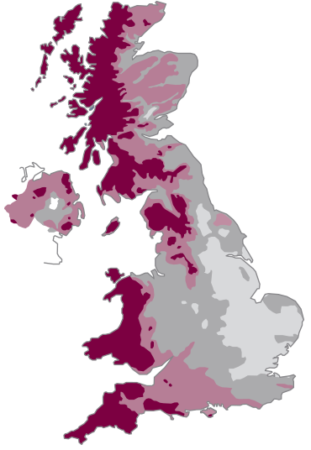

The location is important as well, as it will impact the exposure. For example, buildings positioned on slopes, hills or coastal areas are classified as high exposure. Within the UK, depending on the wind-driven rain that an area receives on average we have four exposure gradings:

Sheltered: Less than 33

Moderate: 33 less than 56.5

Severe: 56.5 to less than 100

Very severe: 100 or more

In general any area within 30 miles of a west facing coastline is considered to be one of severe exposure.

The exposure grading varies depending on the area and can be identified via the annual driving rain index.

Type of slate

The type of slate depends on the pitch of the roof. For example, small slates are more suitable for steep roofs with free-flowing drainage whereas larger slates are a better choice for lower roof pitches with more exposure.

In Southern England, the most common slate size is 500 x 250mm, and in the North of England and Scotland it is 400 x 250mm.

Slate head lap

The head lap is calculated by measuring the roof pitch against the wind and rain exposure. The thickness of the slate should also be considered, as it reduces the pitch by 3º or more. For example, in lower pitches, the lap must be increased to help resist wind uplift and capillary action, especially if they’re highly exposed.

Key considerations when using and preparing to use slates

Grading and sorting

The grading and selection of natural slates is extremely important to achieve a sleek and professional finish. All slates, no matter what grade they are, must be sorted. The best grades, such as our R Excellence selection, will be more consistent, but all slates need to be graded and sorted into at least three or four thicknesses once removed from their pallets.

During this process, it is also important to check the slates soundness by lightly tapping each slate. Once slates have been graded and checked for imperfections, fixing can begin, leaving aside any broken or unusable slates for under-eaves, tops or halves, etc.

Slates should be laid with the thicker slates being installed at the eave. The slates should then be laid diminishing thicknesses until the thinnest slates are at the top.

Methods of fixing slates

The British Standard Code of Practice (BS 5534) identifies two installation methods: nailing and hook fixing. Natural roofing slates are usually fixed to a batten in England and to a sarking board in areas of severe exposure throughout Scotland.

Nail fixing

Pre-hold slates are a time efficient option for those who wish to use the nail fixing method. However, if on-site holing is required, you should choose the centre and head fixing, holing by hand or machine, one slate at a time. You can find detailed information about these methods in our installation guide. Additionally, slate nails should be either aluminium alloy or copper, or silicone bronze or stainless steel in coastal areas.

Holing (Centre Fixing)

Hole from the bed of the slate (its reverse), this allows the nail head to be located in the recess on the face of the slate, which is created by the holing process. Each slate should be

holed twice.

The head of the slate should lay approximately halfway on to the batten (i.e. 25mm on to the batten) leaving 25mm to nail into. A clearance of 6–12mm is recommended.

Holes should be located between 20– 25mm from the long edge of the slate. The underlay is then fixed and the roof marked to the batten gauge. This may require adjusting in order to create equal course numbers. The required lap should only ever be increased not decreased.

Holing (Head Fixing)

Head or shoulder fixing is only acceptable for small or heavy slates. This practice is more common in Scotland. In Scottish practice it is common to nail slates to softwood sarking boards using a combination of shoulder-nailing and centrenailing to resist wind uplift. If this method is adopted it is recommended that every third course is nailed twice.

Holing by Hand

Wherever possible, machine holing is preferable. Holing by hand should only be considered when a small amount of slates need re-holing for repairs or when a hole needs to be repositioned in-situ.

To hole a slate with a spike hammer, position the slate flatly over a narrow iron. When measuring the position of the holes ensure the thinner end of the slate is at the top when fixed.

Holing by machine

If slates are machine holed it is recommended that only one slate be holed at a time. If the machine uses a punching method then attention should be paid to the risk of damage.

The holing machine will need to be well maintained and adjusted regularly. For this reason a boring method is preferable. Nails are required to be 20-25mm longer than two thicknesses of slate.

Hook fixing

When opting for hook fixing method, it is important to know that hook fixings may not be suitable for large slates, which experience a greater wind uplift than smaller slates, and for pitches above 75º or below 25º. Slate hooks are available with straight or crimped shanks. However, crimped shanks reduce the capillary action and should be used for roof pitches below 30º.

In addition, when fixing slates with hooks all perimeter slates should be nailed and hooked for health and safety reasons. Slate hooks should be stainless steel and be formed from stainless steel wire.

Hook fixing can have many advantages, such as reduced labour costs, fewer breakages or a simpler replacement process. This fixing method is very common in Europe, particularly in France and Belgium.

Ventilation

Ventilation is also important. Roof space ventilation is the most effective and economic method of keeping harmful condensation to a minimum, and it can be achieved by providing eaves through to the ridge ventilation. Ventilation also depends on the construction method used, that can be ‘cold roof’ or ‘warm roof’. A warm roof has the insulation at rafter level whereas a cold roof has insulation at the ceiling level.

It is important to consider a ventilator which enables ventilation or extraction through slate roofs. Good ventilation will help reduce costs and dangers attributed to winter weather. Even in summer, without proper ventilation, heat can rise and cause moisture to build up.