7 Curious facts on roofing slate

I have been doing research on roofing slate for many years. During this time, I’ve found some interesting facts about roofing slate, relating many different fields such as peculiar uses, unknown properties, and geological features, among others. For example, did you know that…?

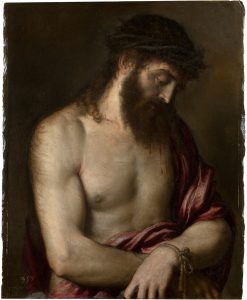

Titian (1490-1576), one of the most important painters from the Italian Renascence, used roofing slate as support for some of his paints. Indeed, the flat, plane sheets of slate from Ligury, in Italy, had been used for roofing for centuries. However, only a few painters knew how to prepare the slate for painting. If the slate is not properly prepared, the paint will not last for centuries.

Titian was aware of this method, which is nowadays lost, but that I think was something like the enameling or marbleizing of slate applied during the 19th century. The slate was submerged in several oil and varnish baths, and then dried in a special oven.

Nowadays, you can find some of these paints in some of the most important art museums, such El Prado Museum in Madrid.

- How do you call a turkey? Using a turkey call. And, what are the best turkey calls in the world? Those made with roofing slate.Some years ago, during the 2016 conference of the National Slate Conference (NSA), in Pennsylvania, we visited the Penn Big Bed Slate Company, owned by Mr. Pete Papay. Besides the tons of roofing slate, I saw several slate circles, like 8 centimeters diameter (or 3,15 inches if you prefer).

What’s this? I answered, Turkey calls! was the response. Yes, with slate you can make a turkey call, and make an particularly annoying noise that is very appreciated by turkeys. Search for it in Youtube.

- Most of slates are black or greyish-black. Because of that, direct sunlight heats them up to 80 °C, or 180 °F. Enough to fry an egg. Can we take advantage of this energy? The answer is yes. Some years ago, the R&D department of CUPA PIZARRAS developed Thermoslate, a modular panel that uses the sun energy to heat the domestic water.

Roofing slate has a property called thermal inertia, that is, it takes a while for the slate to reach temperature compared with air’s temperature, but once is heated, slate will keep it for a while after the sunset.

- Slates are rather common over the Earth’s crust, but only a few can be used for roofing. You need homogeneous, clean and huge slate outcrops.

There are three color families, black-grey, green and purple-red. Color is given by small proportions of some minerals, and is also the reflect of the environmental conditions during the sedimentation of the clay which will be transformed into slate by tectonic forces.

Green and purple-red slate usually occur together, since they are formed in shallow waters, while black-grey slates correspond to deep waters.

- Besides color, lithology (or type of rock) is another distinctive feature for roofing slates. A roofing slate is a metamorphic rock used for covering roofs, in other words, a natural rock used as construction material.

But not all roofing slates are slates. Depending on the metamorphic degree (how much the Earth has cooked the rock) we have, from lower to higher: low-grade slate, slate, phyllite, and mica-schist. The best technical values for roofing correspond to slates and phyllites.

- Ancient cultures settling in areas with slate outcrops have taken advantage of this rock not just for building shelters but also for make tools and weapons. For example, native North Americans from Newfoundland used the Ulu knife, a tool very useful to butcher fish and meat.

Slate arrowheads and axes were common in the territories of modern Norway. It is not very difficult to cut and polish a piece of slate and make a sharp edge tool. You can try using sandpaper and some patience.

- During the quarrying process, if you let the blocks dry they will lose fissility, so it will be practically impossible to split them into thin tiles. This is because of the loss of water.While slate is in the mountain or rock massif, the rock is kept wet due to rain and other natural sources of water. Once extracted, it begins a drying process, which depends greatly on the temperature and the direct sunlight.

Slate quarrymen all over the world always do the same: keep blocks wet, generally spraying water over them. The reason of this is that the water that leaves is contained in between the slate minerals, which are planar, like a pile or microscopic cards.

This water is acting as a “lubricant”, and once has left, splitting slate into thin tiles becomes very difficult, or virtually impossible. Besides, a dried block will not reabsorb the water, so you will have to use it for another purpose, such as paving.

This article is part of a series written by the Geologist and slate consultant Víctor Cárdenes, where you can find interesting features about natural slate. For example: how can you recognize quality in roofing slate? If you want to receive slate stories in your email on a regular basis, subscribe here to our monthly newsletter.

Titian (1490-1576), one of the most important painters from the Italian Renascence, used roofing slate as support for some of his paints. Indeed, the flat, plane sheets of slate from Ligury, in Italy, had been used for roofing for centuries. However, only a few painters knew how to prepare the slate for painting. If the slate is not properly prepared, the paint will not last for centuries.

Titian (1490-1576), one of the most important painters from the Italian Renascence, used roofing slate as support for some of his paints. Indeed, the flat, plane sheets of slate from Ligury, in Italy, had been used for roofing for centuries. However, only a few painters knew how to prepare the slate for painting. If the slate is not properly prepared, the paint will not last for centuries.